When hydrogen producers talk about reducing costs, the conversation often turns to energy price. But another basic concept playing a critical role in hydrogen economics — electrolyser efficiency.

And not just “headline efficiency” from a datasheet. We’re talking about how efficiency varies across the load curve, and how that matters when you’re optimising your electrolyser hour by hour across volatile electricity markets.

At FLOAT Energy, we help hydrogen producers optimise dispatch across various power markets. So we see this question often:

“Should I ramp down the electrolyser when prices are marginal, or keep it running at full load?”

The answer isn’t always obvious. But your efficiency curve — and a real-world dispatch profile — offer useful clues. If you want to see more detail on our optimiser then check this out.

The Reality: Efficiency Isn’t Constant

Electrolysers are not equally efficient at all loads. In fact, most PEM and alkaline units perform best around 20–40% of full load. At this point:

- Stack over-potentials are manageable

- BoP (balance of plant) systems are active, but not overworked

- Heat, gas separation, and electrical systems operate stably

- You achieve the lowest energy consumption per kg of hydrogen

Push the system harder — toward 90–100% load — and efficiency typically declines due to:

- Increased resistive losses

- Higher thermal demand

- Steeper voltage rise across the stack

At the opposite extreme — below ~20% load — efficiency collapses again. BoP loads dominate, and maintaining safe gas separation becomes difficult. Most OEMs set a turndown limit near this threshold.

What you’re left with is a asymmetric U-shaped efficiency curve — and a system that’s only truly optimal at part load.

But Here’s the Twist: You Still Run at Full Load Most of the Time

In theory, you’d want to sit in that 20–40% sweet spot. In practice? That’s not how real-world operation looks.

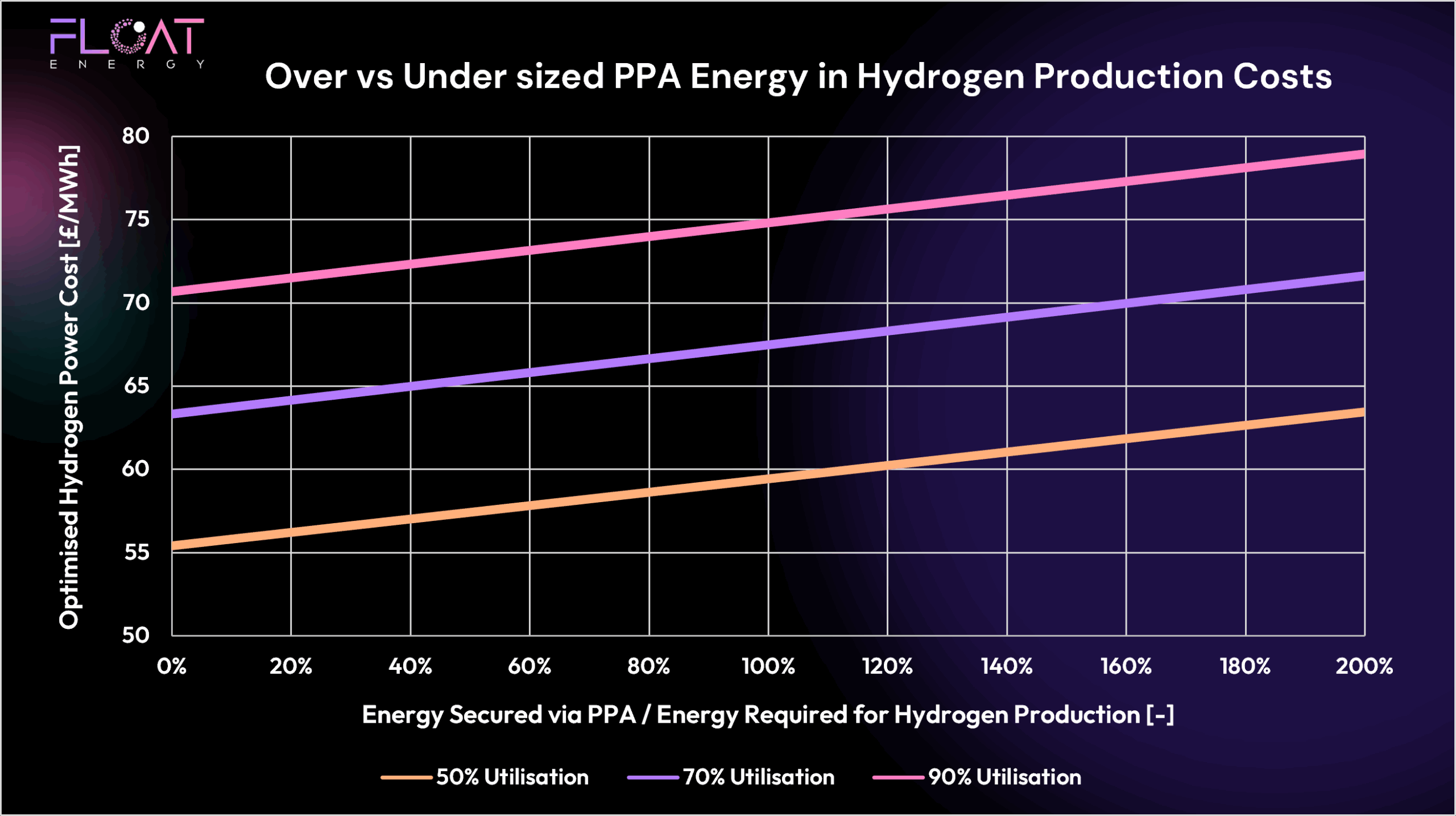

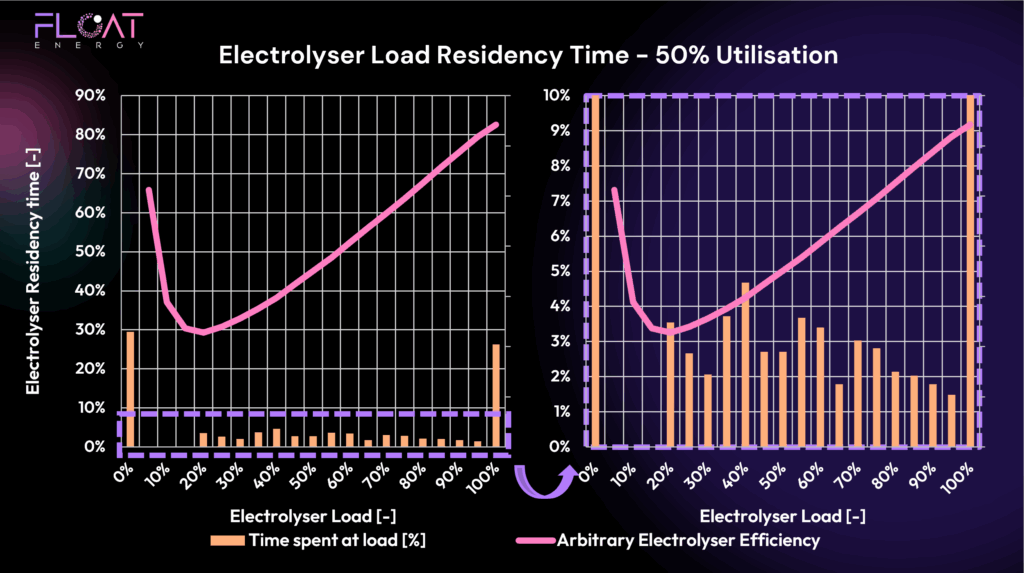

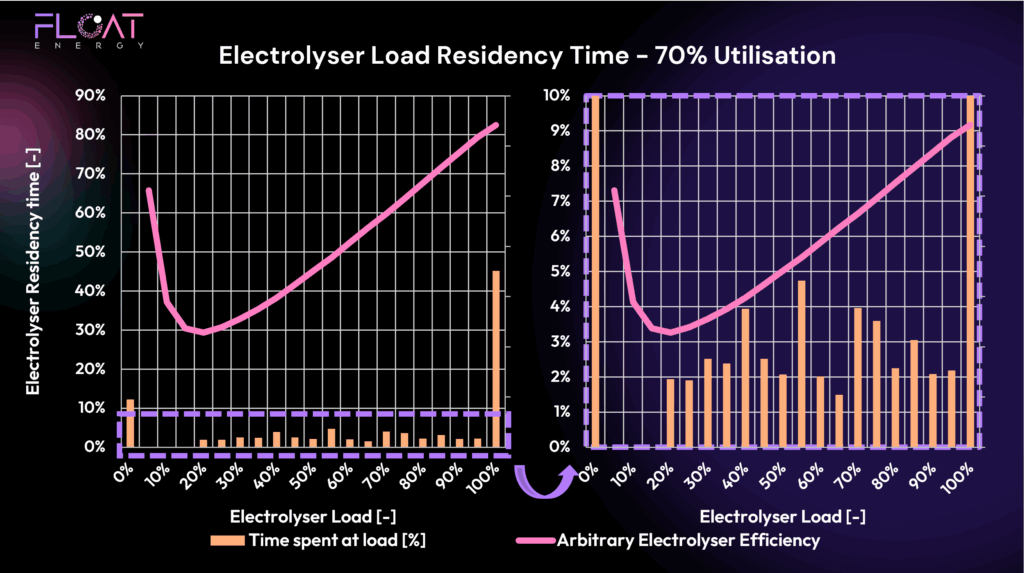

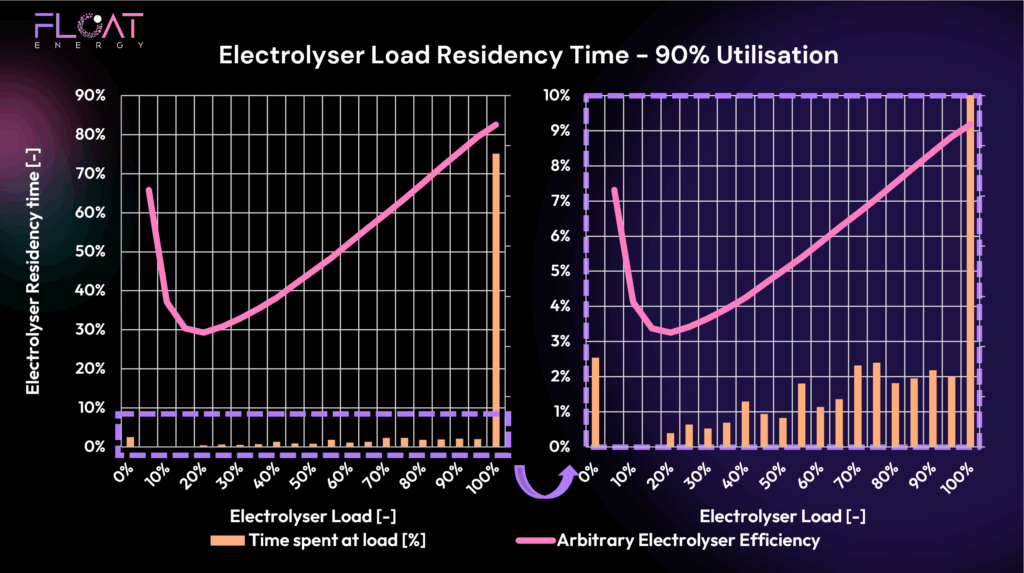

Below are dispatch results from our optimiser, using 2024 power prices and running an electrolyser at utilisations of 50%, 70%, and 90%. The orange bars show how often the electrolyser ran at each load level. The pink line is an example efficiency curve of an electrolyser. Before buying an electrolyser, make sure you get this curve!

At 50% utilisation:

- Full-load operation is already dominant

- Efficiency-optimal partial loads (20–40%) are used, but less frequently

At 70% utilisation:

- Full-load operation becomes the norm

- Lower-load flexibility is used to chase low-price windows and fill gaps

At 90% utilisation:

- The system spends most of its time at 100% load

- Sub-optimal efficiency, but required to meet volume targets

Why Run at Full Load if It’s Less Efficient?

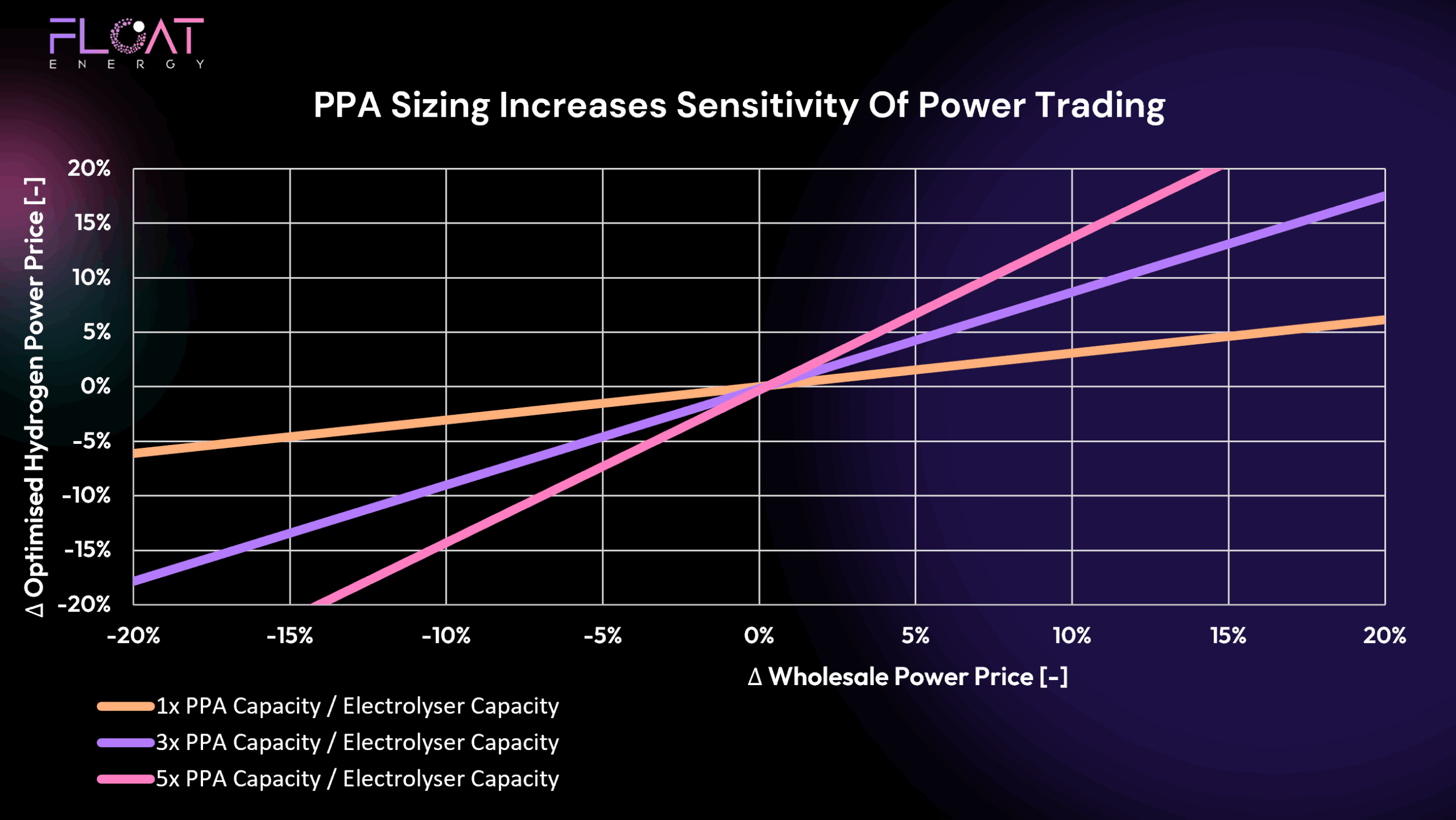

Because electricity price variability — not efficiency — is the dominant driver.

If you can buy power at £30/MWh:

- Running at 50 kWh/kg (part load) → £1.50/kg hydrogen

- Running at 55 kWh/kg (full load) → £1.65/kg hydrogen

Sure, full load is 10% less efficient — but in a few hours, that price might have swung up to £120/MWh. If that’s true then it’s worth suffering the efficiency loss in the electrolyser to avoid the x4 higher power cost forecast in the future. Especially if:

- You need to hit offtake commitments

- Hydrogen storage is limited

- A price spike is coming, and you want to stock up

That’s why our optimiser frequently chooses full load during low-price windows.

Why You Still Can’t Ignore the Efficiency Curve

Now for the nuance: you don’t only run at full load.

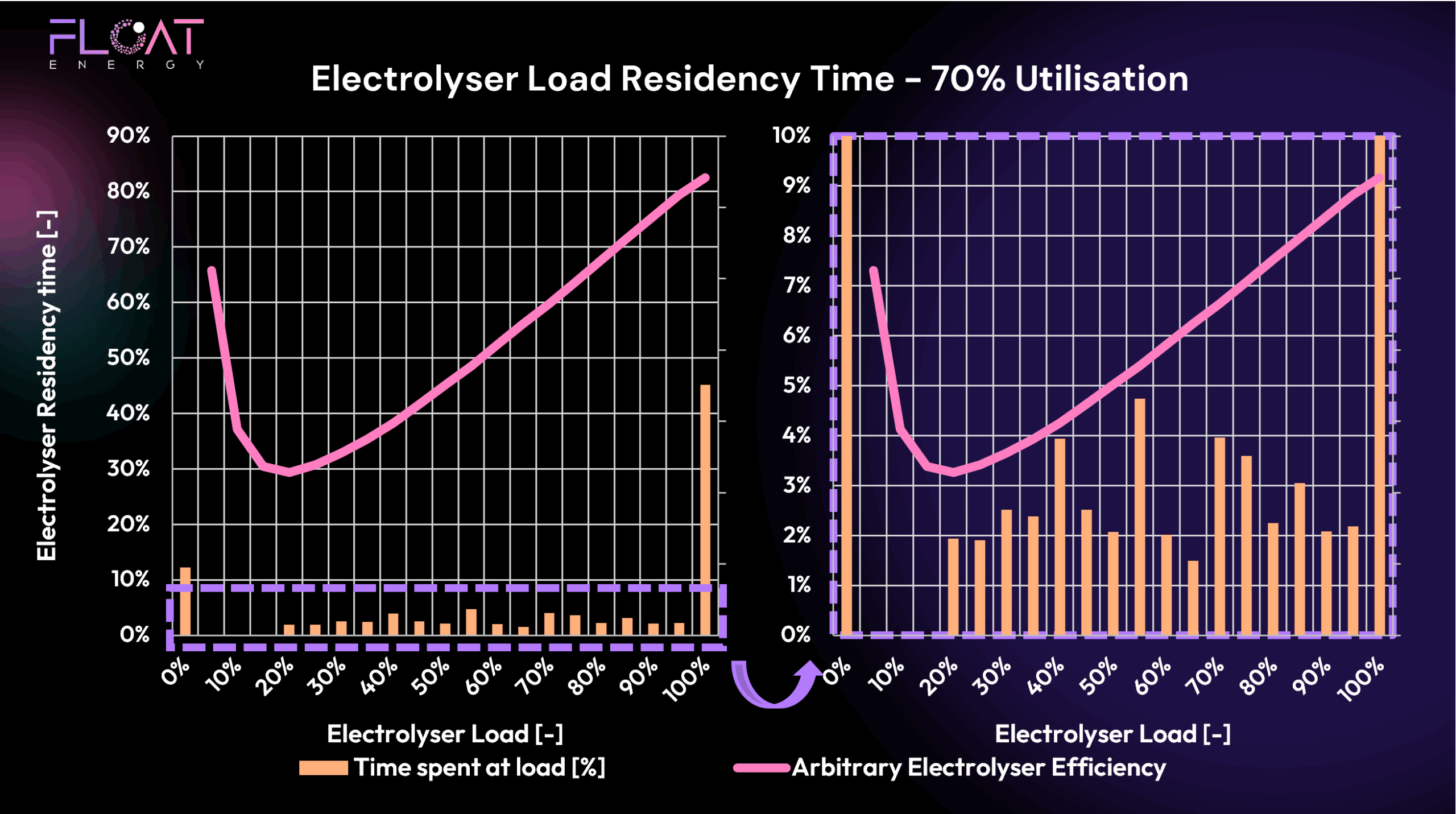

Even at 90% annual utilisation, the optimiser spends time at 60%, 70%, 80% — and even dips down to 30–50% in certain periods.

That’s because:

- Price dips don’t always last long enough for a full cycle

- CO₂ intensity rules may limit the run hours

- Storage, ramping limits, and the electrolyser warranty introduce constraints

This is where efficiency at part load matters. You might spend 30–40% of the year at partial load. This isn’t an insignificant amount of time. When power prices allow, small efficiency gains can make a difference.

So, it’s not about picking efficiency at one load. It’s about understanding how your efficiency curve interacts with your dispatch profile over a full year.

So What’s the Right Strategy?

The most cost-effective electrolyser dispatch usually comes from combining:

This is why FLOAT Energy’s optimisation engine includes:

- Load-dependent efficiency curves

- Power price forecasts across all markets

- Startup/shutdown cost modelling

- Real-time dispatch optimisation

Final Thought: Optimise the Curve, Not Just the Point

Hydrogen plants don’t operate at one fixed load. They move. Flex with price. Respond to demand. The load curve shows this:

You don’t always run at full load — and even when you do, the rest of the curve still matters.

Finally, our optimiser generates more value from switching off the electrolyser rather than running at part load or close to turndown. So in a future blog we’ll take a look at turndown.

FLOAT’s optimiser helps you capture value across the full range of possible operations — not just in ideal conditions, but in real, market-driven dispatch.

Let us show you how.