We’re now going to talk about putting optimisation into practice with some real operation examples.

In Part 1, we explained how hydrogen producers today face a complex operational challenge. Energy prices are volatile, carbon intensity changes constantly, and staying compliant with green hydrogen standards while keeping costs down is far from straightforward. Once your plant is operational, the focus shifts from “what should I build?” to “how do I run this efficiently — and stay compliant?” That’s where FLOAT really earns its keep.

Our Opti-mate platform actively manages your plant’s production in real time, optimising around your key goals:

⚡ Minimise energy costs

By forecasting electricity prices and dynamically adjusting production schedules, Opti-mate shifts production away from expensive hours — whether you’re sourcing power from PPAs, the grid, or both.

🌍 Ensure compliance with green hydrogen standards

Opti-mate forecasts carbon intensity and ensures your plant operates within thresholds like the UK’s Low Carbon Hydrogen Standard.

📦 Meet hydrogen output targets reliably

We help you deliver your contracted hydrogen volumes on time, accounting for uncertainty in demand and balancing production to avoid over- or under-supply.

🔧 Protect your electrolyser and maximise efficiency

Opti-mate respects technical limits such as ramp rates, minimum turndown, and cycling constraints to ensure high efficiency without risking equipment damage.

The result: you operate confidently, flexibly, and sustainably — without spreadsheets, guesswork, or compliance anxiety.

What Does That Look Like in Practice?

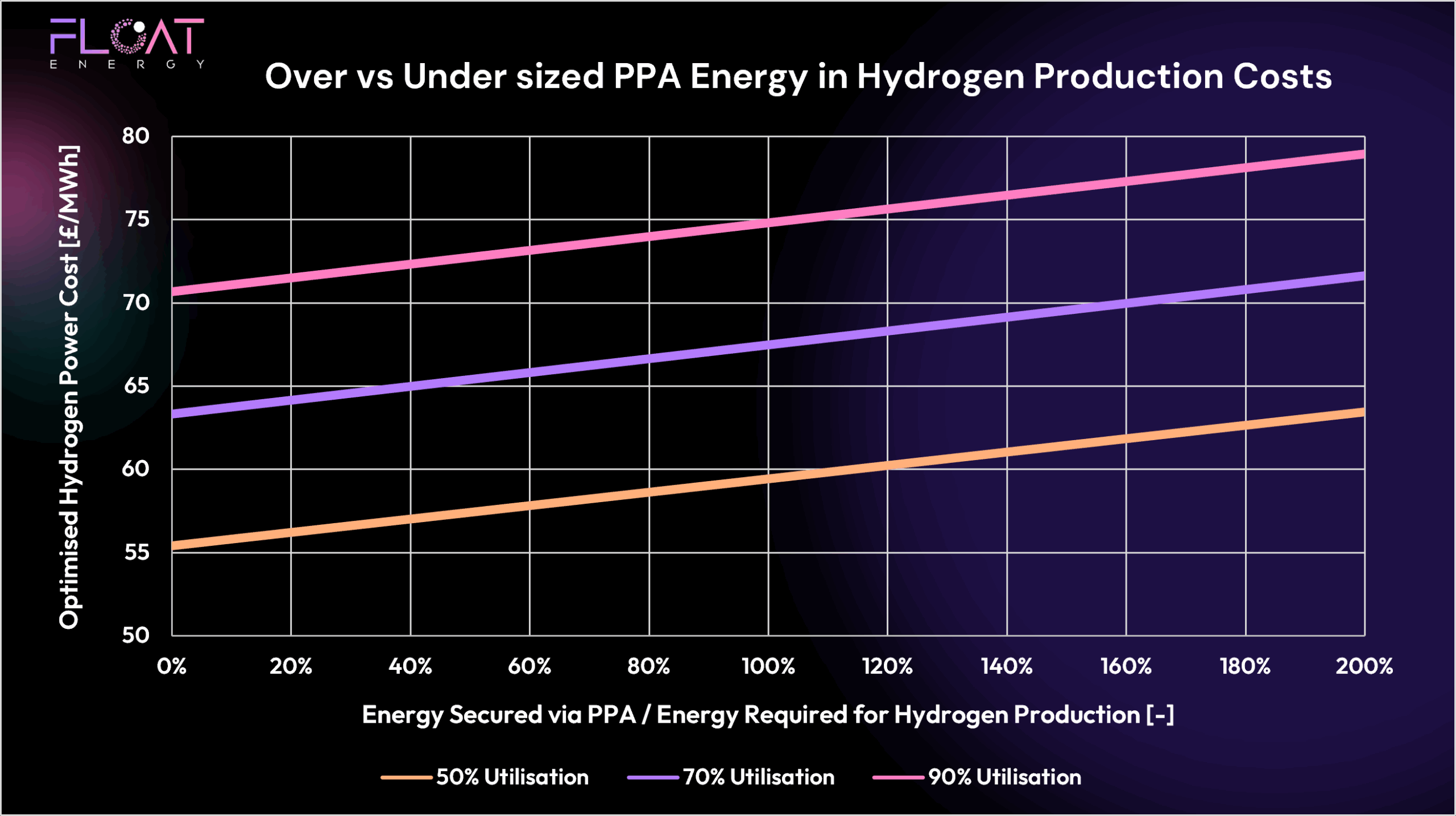

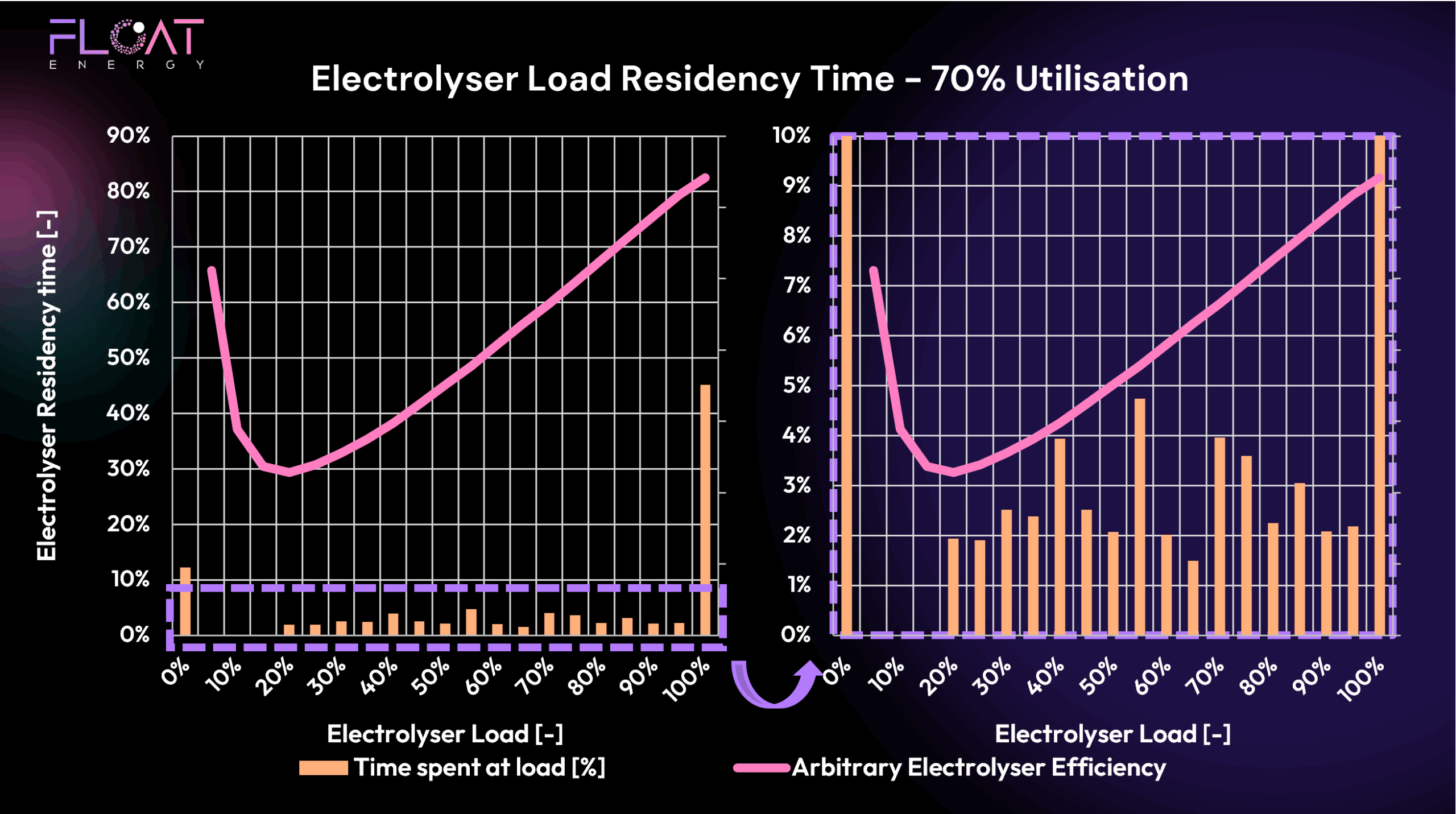

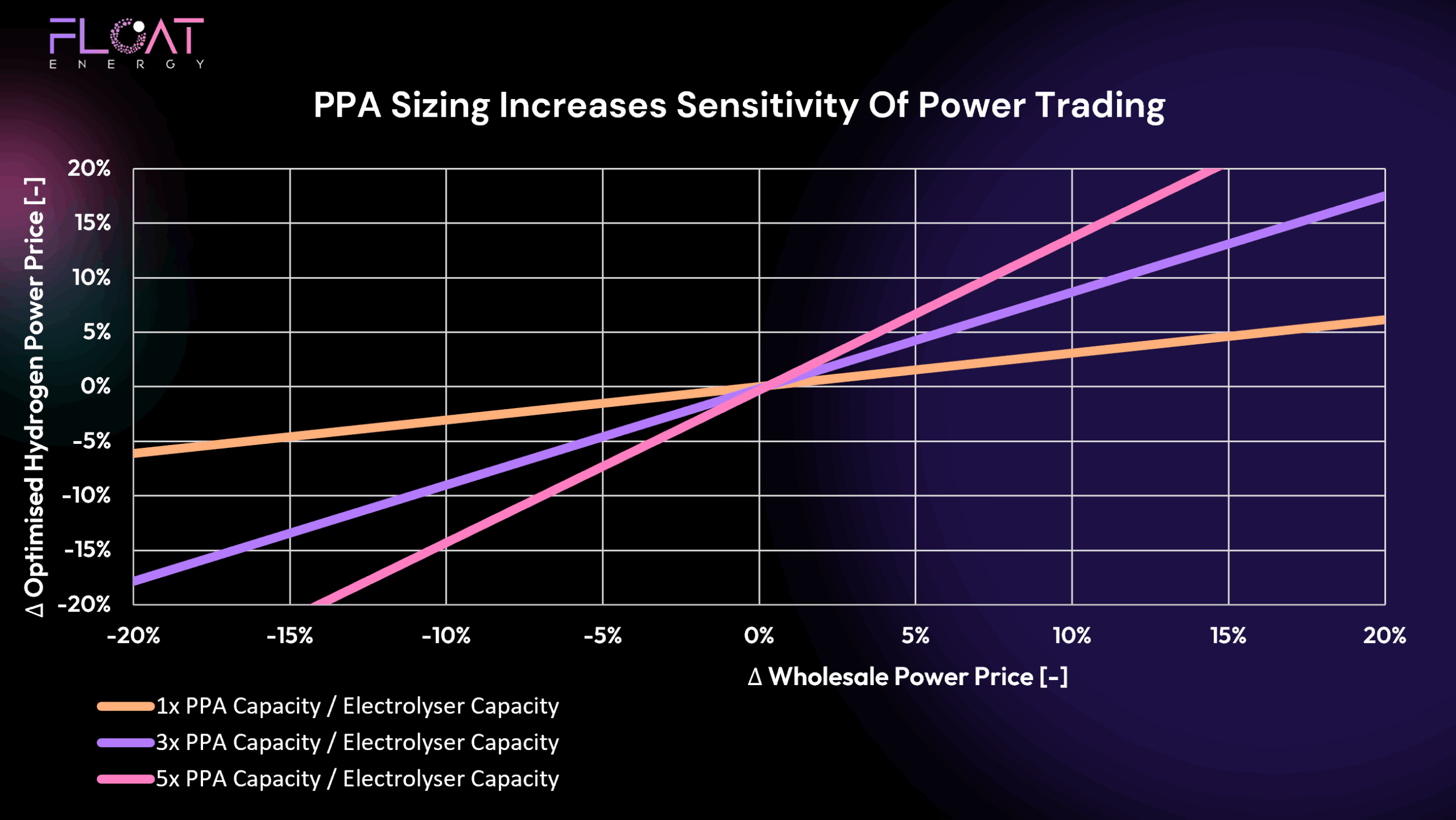

We’ve put together a few simple charts to show how Opti-mate makes smart, real-world decisions.

Each of the graphs below shows how the production schedule changes depending on which constraints are active:

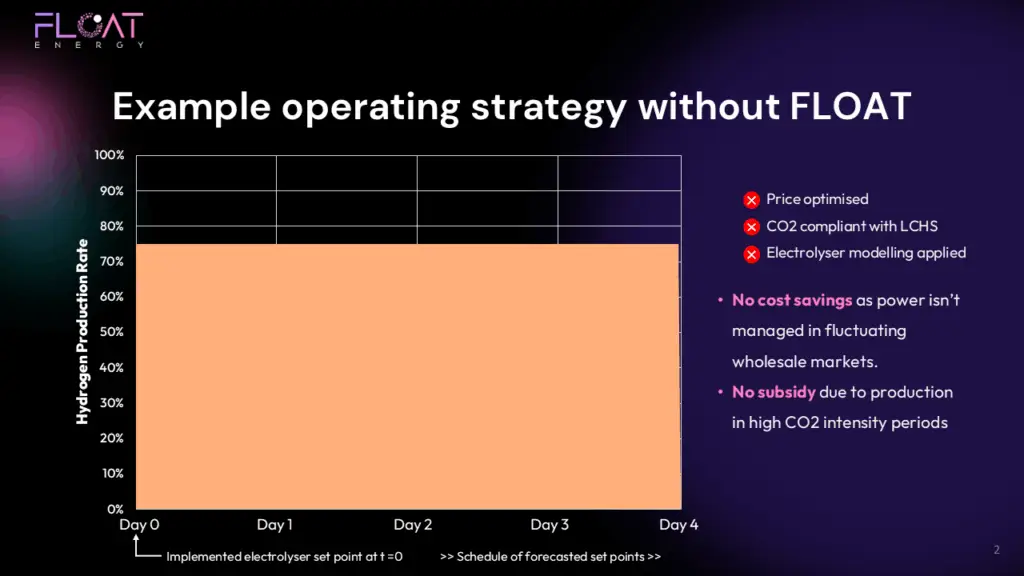

🔹 Base case. Flat Production (No Optimisation)

A hydrogen plant running at a constant utilisation, regardless of price, carbon intensity, or operational conditions. Simple… but expensive and inefficient.

- ❌ Price optimised

- ❌ CO2 compliant with LCHS

- ❌ Electrolyser modelling applied

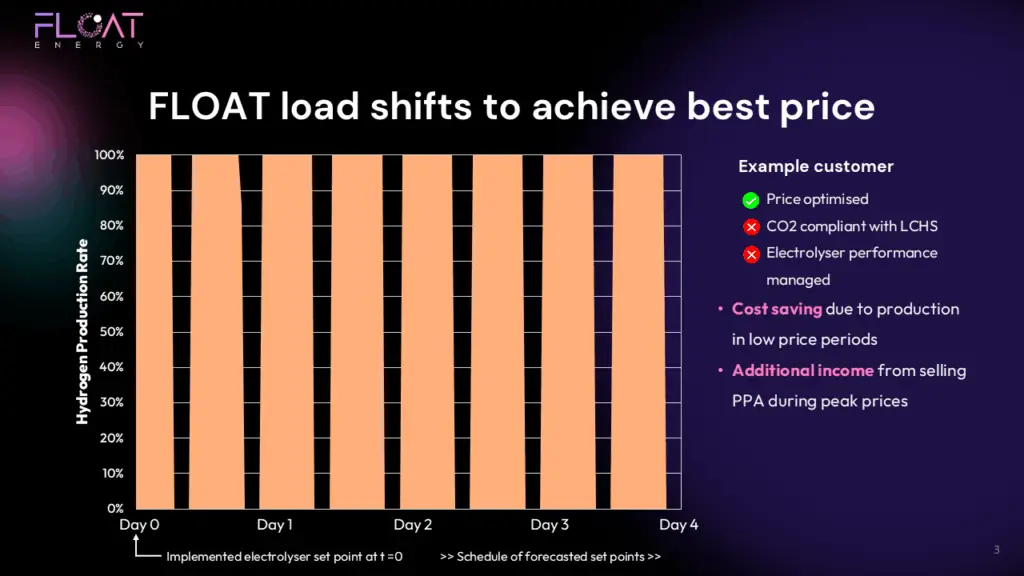

🔹 Optimise for electricity price

FLOAT forecasts power prices and shifts production into the cheapest hours — cutting energy cost by using the same MWh more wisely.

- ✅ Price optimised

- ❌ CO2 compliant with LCHS

- ❌ Electrolyser modelling applied

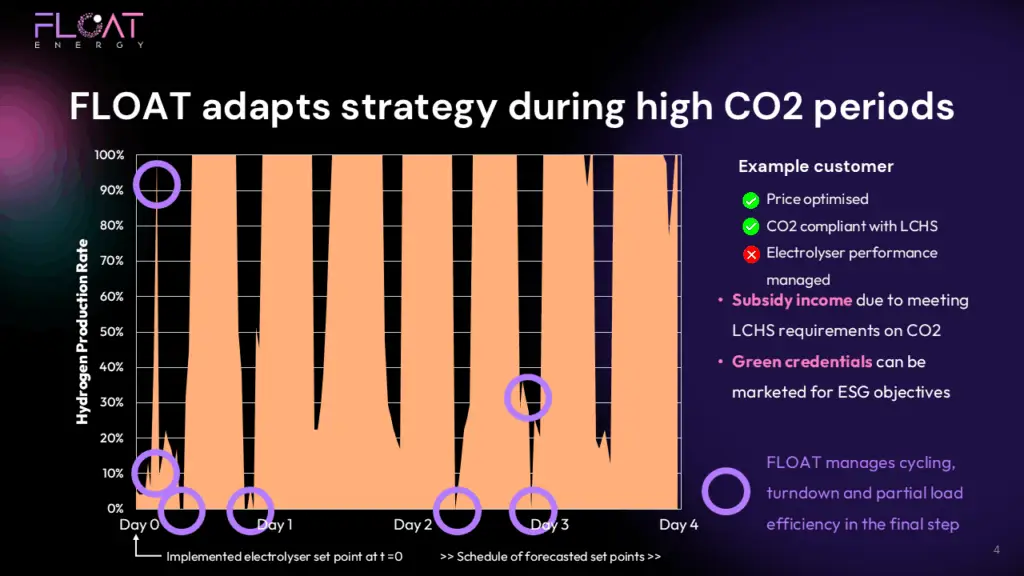

🔹 Carbon-Aware Production

Layered with CO₂ intensity data, FLOAT prioritises production when electricity is cleaner — helping you stay compliant with green hydrogen standards like the UK LCHS. However, this creates high ramp rates and unnecessary cycling (switching the electrolyser on and off in quick succession)

- ✅ Price optimised

- ✅ CO2 compliant with LCHS

- ❌ Electrolyser modelling applied

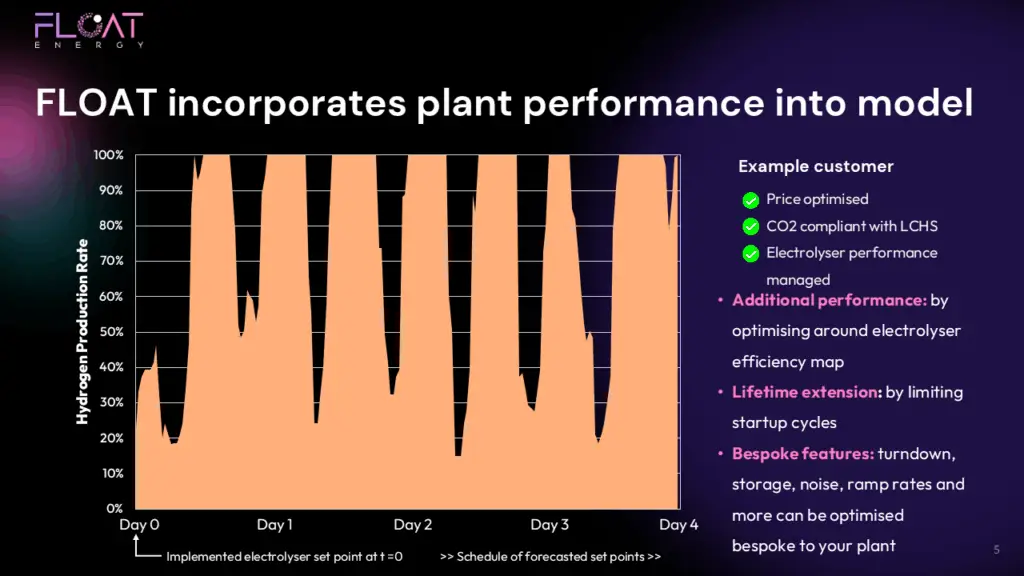

🔹 Fully Optimised Dispatch that considers your plants characteristics

Now the optimiser adds electrolyser characteristics: efficiency curves, turndown limits, ramp rates, and minimum runtimes. This is the actual production plan your plant can follow without damaging equipment — while still cutting cost and meeting carbon targets. If you have specific electrolyser warranty requirements then we programme this into the optimiser.

- ✅ Price optimised

- ✅ CO2 compliant with LCHS

- ✅ Electrolyser modelling applied

These charts are a simplified view — in practice, FLOAT runs thousands of possible schedules and picks the best one that will perform across a range of forecasted outcomes.

📩 Want to see what this would look like for your specific site, with your PPA and plant specs? Get in touch with us to simulate it.

What’s Coming Next – Monthly Energy Price Series

Each month, we’ll publish a performance update — showing how our optimiser reacts to real market conditions and what a hydrogen plant could’ve saved (or spent) through smart dispatch.

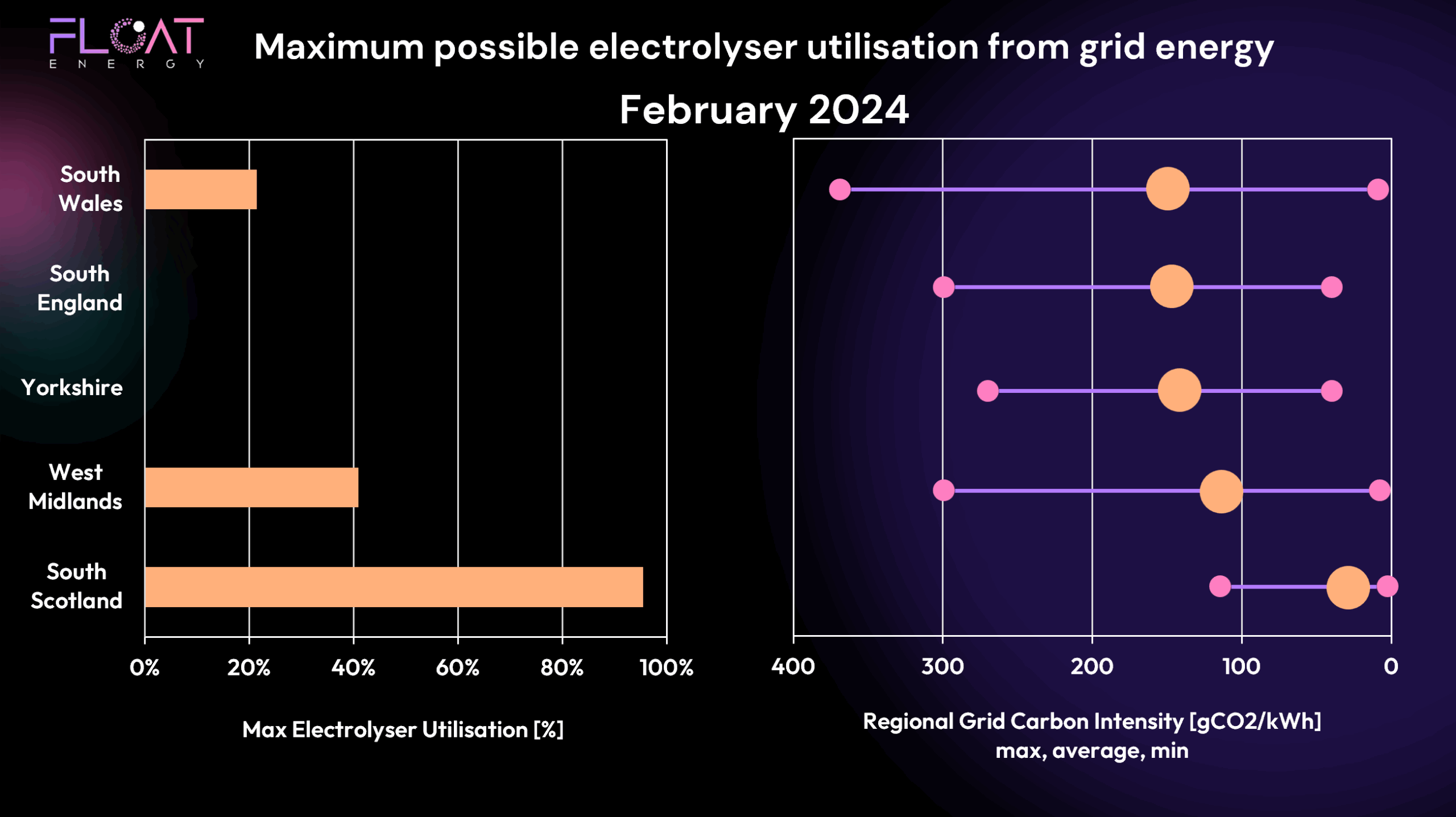

We’ll start with a base case using:

- 70% utilisation

- A PEM electrolyser

- South Scotland CO₂ intensity data

Want to see results based on your own project? Just ask.

Get in touch through our website, email or LinkedIn to see how optimisation changes the economics of hydrogen production!