Hydrogen producers today face a tricky puzzle: energy markets are volatile, the carbon intensity of the grid changes every second, project investors are demanding bankability, and customers require green hydrogen at lower costs.

Whether you’re using grid power, renewables, or a hybrid mix, knowing how and when to run your electrolyser can be the difference between profit and loss.

We saw a gap. The models we’ve seen don’t capture the real dynamics of flexible hydrogen production — especially when you’ve got multiple PPAs, intermittent power, carbon intensity constraints, different electrolyser types, and varying storage setups. You get the idea…

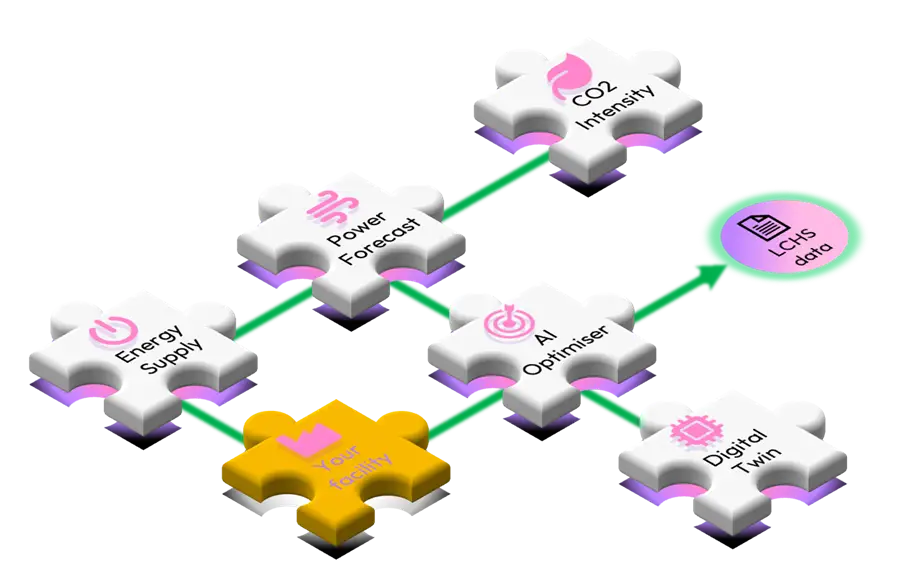

So we built Opti-mate — a flexible, computationally efficient optimisation platform that lets hydrogen producers simulate dispatch strategies before construction and optimise schedules in real-time once operational.

It’s your tool to automate production scheduling, reduce energy cost, and stay compliant with carbon intensity rules like the UK Low Carbon Hydrogen Standard.

The Hydrogen Energy Cost Series…

We believe in Opti-mate so much that we’re starting a monthly series showing the optimised energy price for a sample hydrogen plant — a sort of benchmark for what green hydrogen could cost under smart dispatch.

“…but my project is unique”

Of course it is. Every hydrogen plant is different — which is exactly why we built a service that adapts to your site, PPAs, offtake agreements, and design constraints.

Get in touch with FLOAT Energy — we’ll work with you to understand your plant and deliver a tailored optimisation solution.

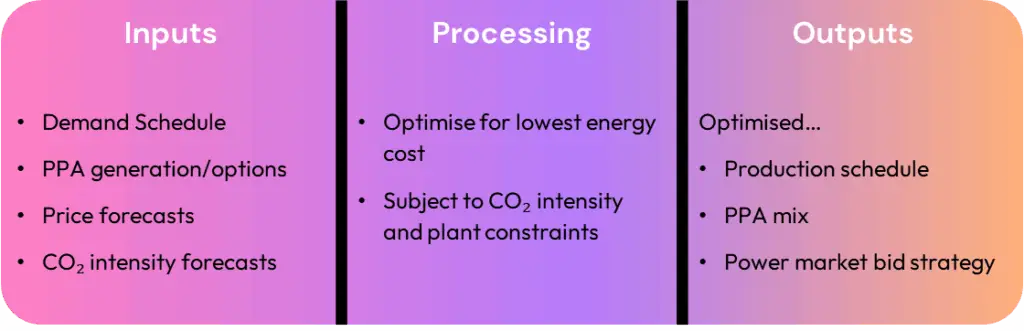

What the Model Does

We’re not giving away the source code (sorry), but here’s a glimpse of what the optimiser handles:

The truth is, we can program Opti-mate to model just about anything — we treat each project like a puzzle, and we enjoy joining the pieces together.

Why It’s Useful

Before Operation, our platform helps clients:

- Benchmark the impact of different PPA and grid mixes

- Optimise their PPA strategy

- Inform plant design (storage size, flexibility, electrolyser type)

- Simulate expected OPEX under real market conditions

- Secure a power hedge that aligns with dispatch strategy

- Build confidence in bankability and investment cases

During Operation, we help clients:

- Optimise daily production schedules

- Balance PPA and grid energy dynamically

- Integrate with existing supplier and PPA contracts

- Send power market bid strategies based on flexibility

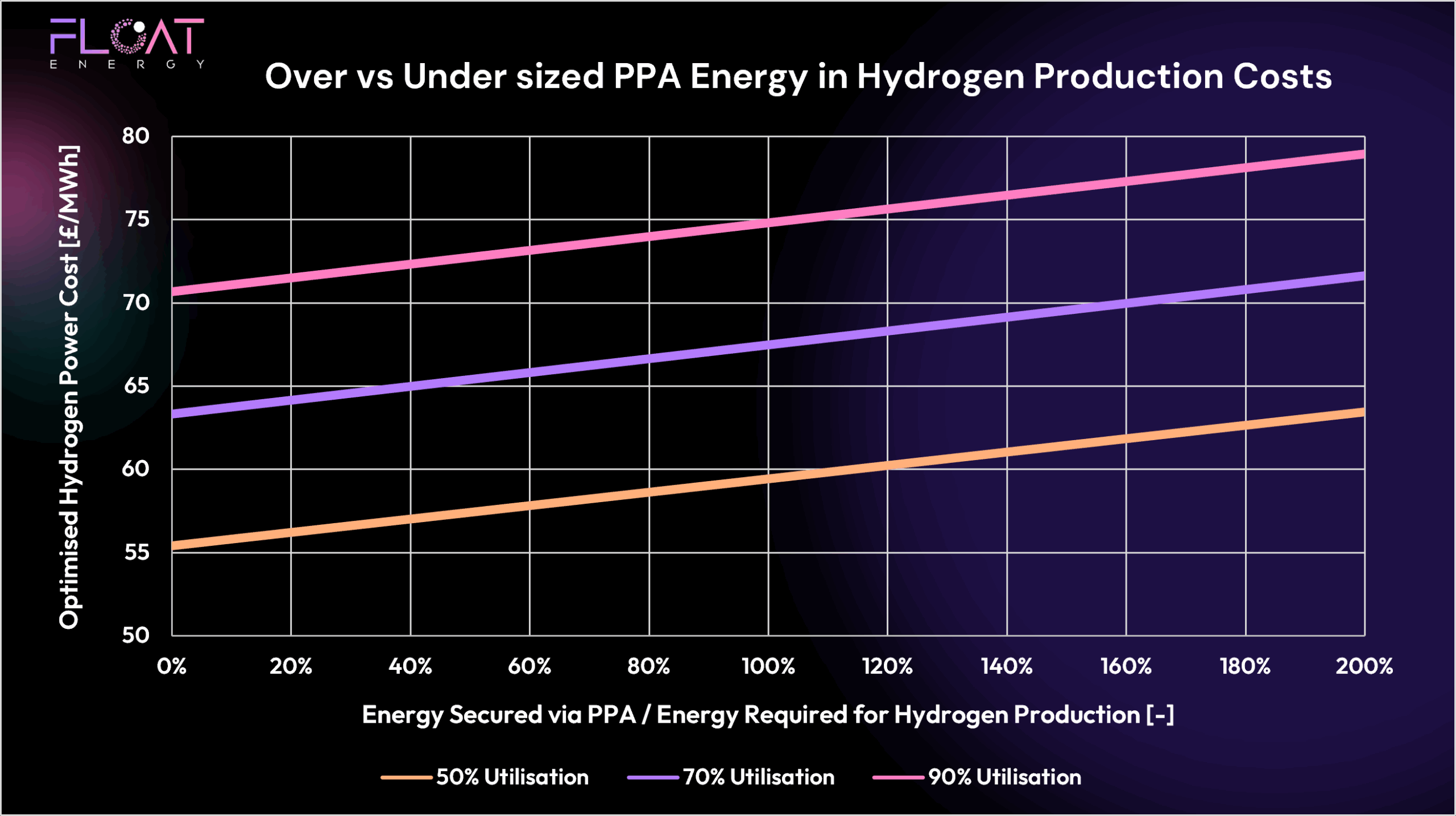

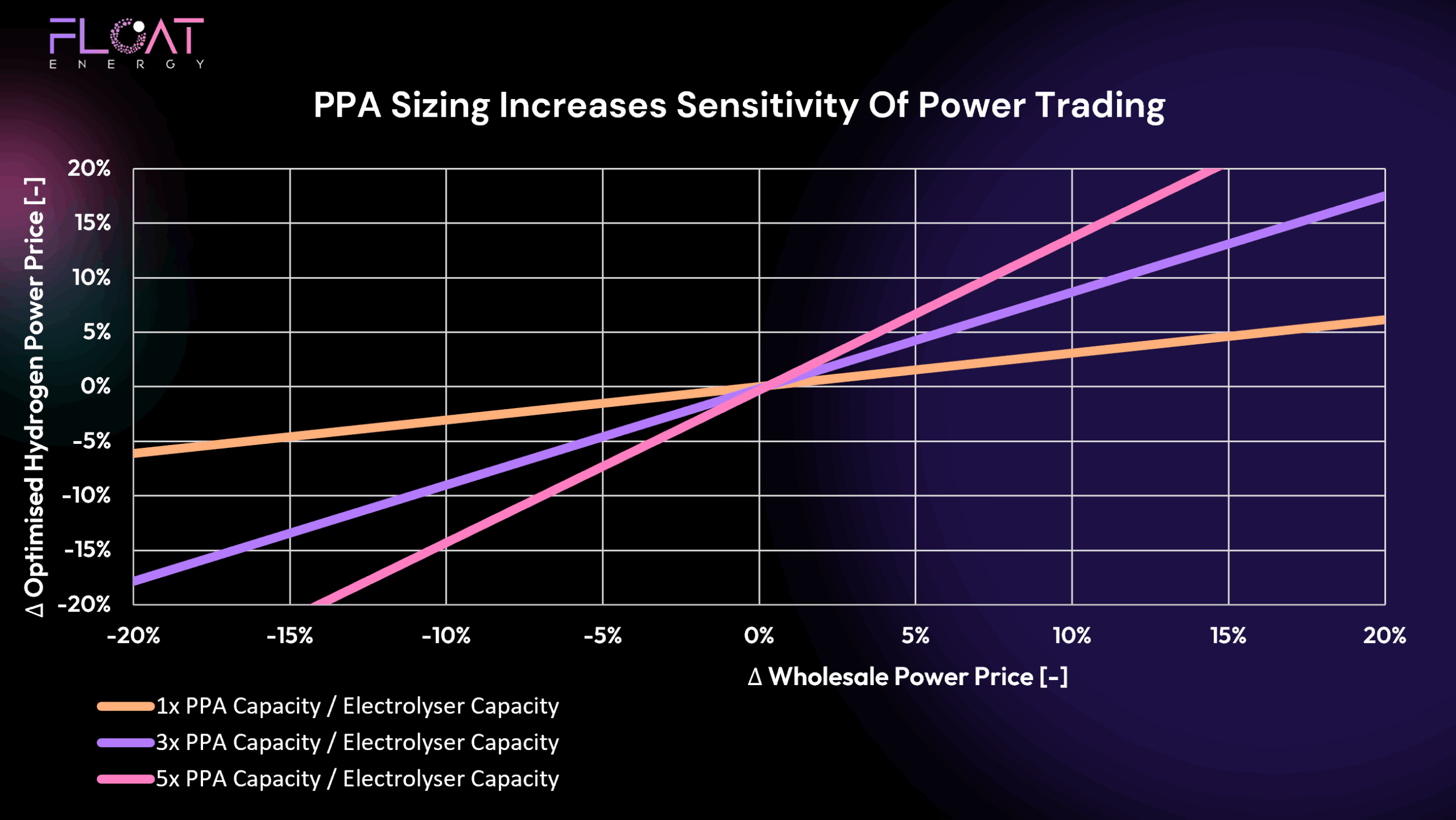

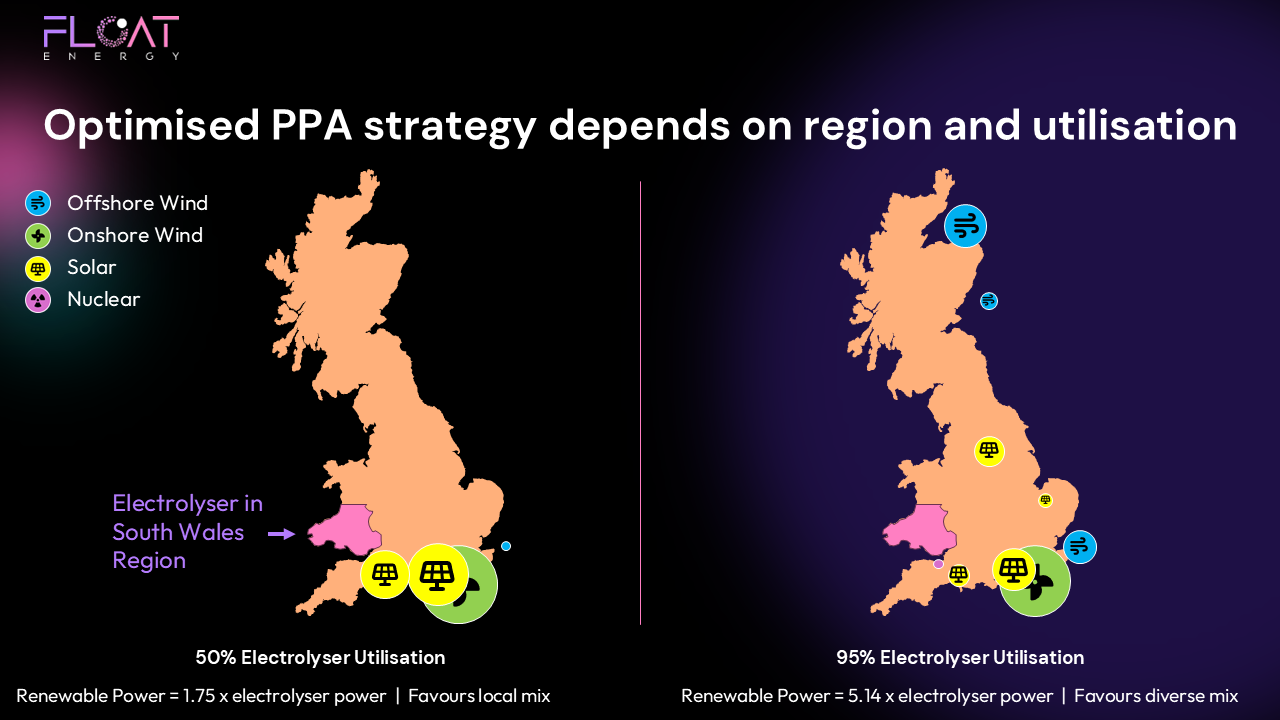

What’s the Best PPA Mix for My Hydrogen Project?

That’s the million-pound question — and it depends entirely on where you are, how flexible your plant is, what generators are offing you and how the PPA is structured.

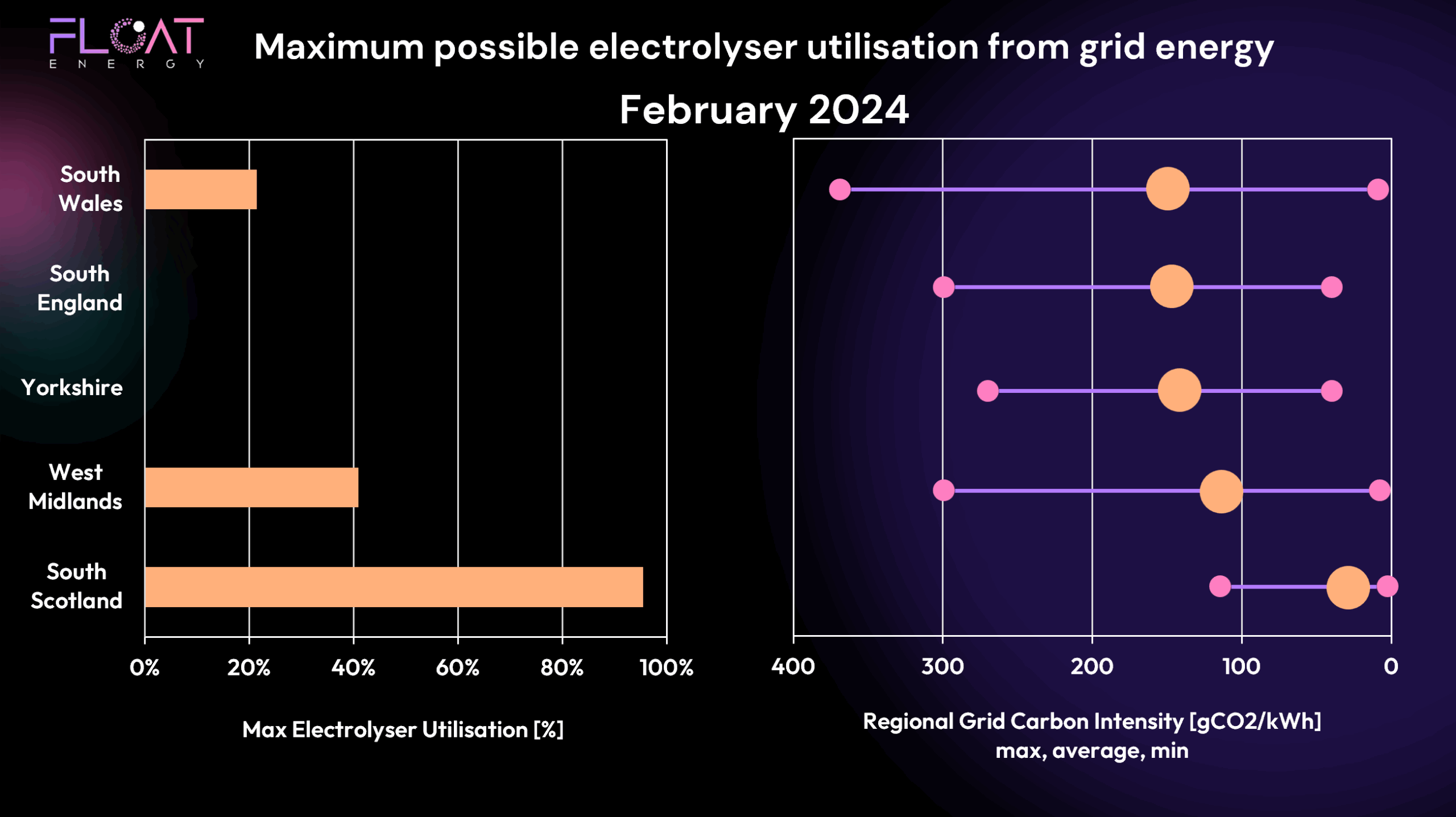

At FLOAT, we use Opti-mate to simulate the value of different generation mixes across multiple UK regions, factoring in:

- Wholesale price

- Regional carbon intensity data

- Hydrogen plant details (e.g. electrolyser constraints and storage)

- Load factor and pricing variability across generation types

We’re not just looking at the cost of a PPA and the average annual yield. We’re simulating thousands of alternative events and finding the optimum generation mix to suit your project over a wide range of outcomes in the long term.

Lets say you undertake a RFQ for PPA in your hydrogen project. Of all the results you get back, which will you go for? Wind? Solar? A mix? What type of mix? FLOAT can optimise the mix for you depending on your project. The differences can be massive

The result? A tailored PPA strategy that balances:

- 💸 Low energy cost

- 🔋 High utilisation

- 🟢 CO₂ compliance

- 📉 Risk-adjusted OPEX

There’s no one-size-fits-all. But there is an optimal strategy — and we can simulate it for your site.

What About Operation? How Do I Ensure I Reduce Energy Costs and Comply with the Standards for Green Hydrogen?

Once your project is operational, the challenge shifts from “what should I build?” to “how do I run this thing efficiently — and stay compliant?”

This is where FLOAT really earns its keep.

We actively manage your plant’s production in real time, optimising around key goals. The most important are:

Minimise energy cost

By forecasting prices, Opti-mate selects when to ramp up or scale back production — whether you’re sourcing power from PPAs, the grid, or both. It automatically shifts production away from expensive hours, helping you capture the cheapest electrons available. We work alongside your existing supplier and PPA arrangements but speak with us if you want a turnkey hydrogen PPA and utility service.

Stay compliant with green hydrogen standards

Opti-mate ensures your production stays within thresholds like those defined in the UK’s Low Carbon Hydrogen Standard. We’re forecasting CO2 intensity of the electricity you consume to ensure you stay within bounds.

Meet your total hydrogen output targets

We know you’re contractually obliged to deliver hydrogen to offtakers. This could be in different forms (pipeline, tube trailers etc). We’ll ensure production meets demand and accounts for any uncertainty in when you expect demand to show up. Production can be balanced down to the minute to ensure your hydrogen delivery targets are met.

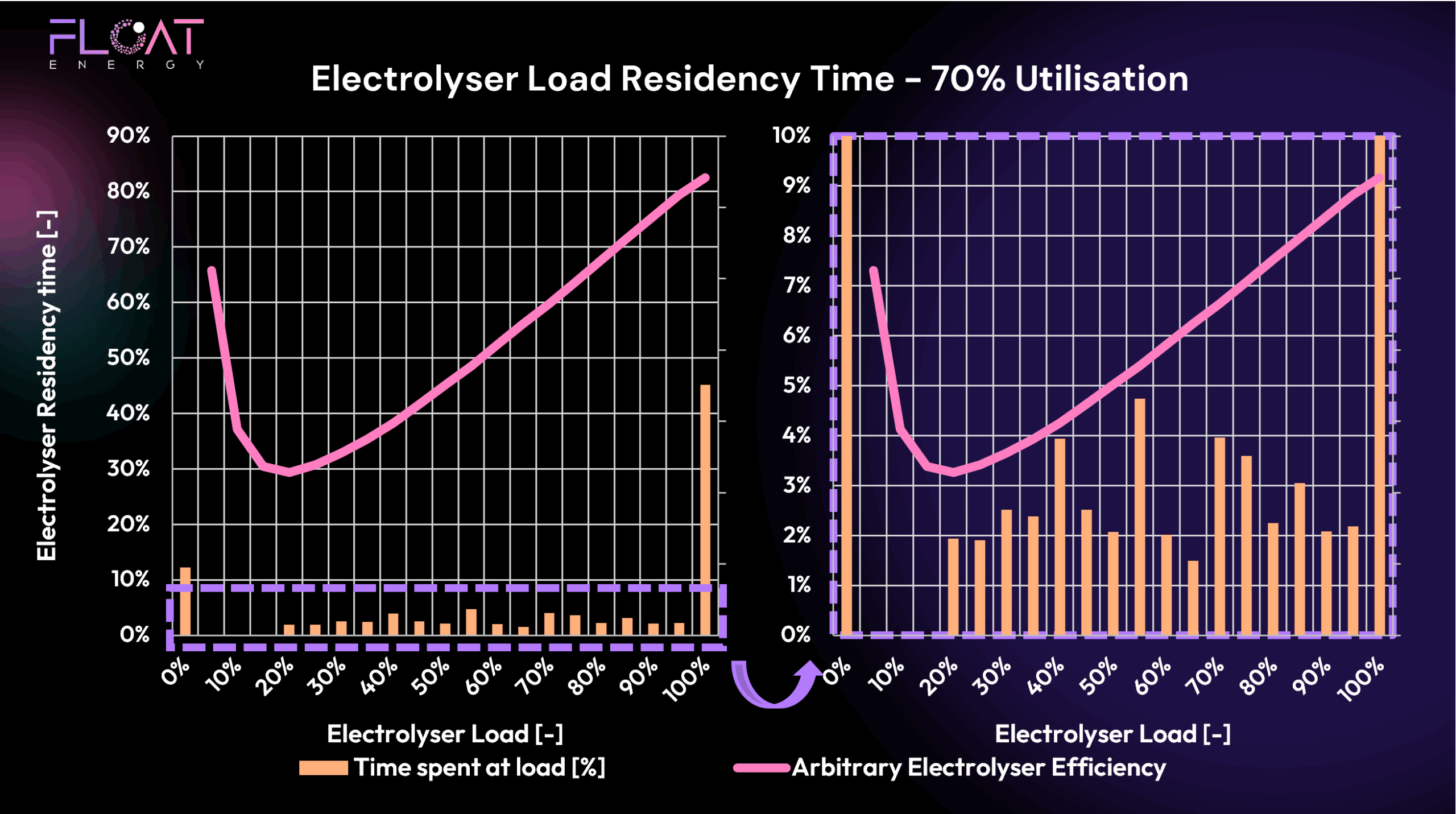

Protect your electrolyser and maximise efficiency

Production flexibility is only valuable if it’s technically viable. The optimiser maximise electrolyser performance by:

- Optimising for best efficiency

- Respecting turndown, cycling and ramp rate limits

The result: you operate confidently, flexibly, and sustainably — without spreadsheets, guesswork, or compliance anxiety.

FLOAT can either run Opti-mate as a standalone software or integrate into your existing operations and supplier framework. Either way, you get the full benefit of automated optimisation.

What Does That Look Like in Practice?

Look for our next article in the series for a real example of optimisation in action. We’ll then see how the optimiser performed across 2024!