How Much Hydrogen Can You Really Produce Using Just Grid Electricity?

Regional differences in grid carbon intensity set hard limits on electrolyser utilisation.

In our monthly energy cost series, we’ve been exploring hydrogen production using only grid electricity, with no assumptions about direct-wire renewables or PPAs. To keep things consistent, we’ve focused on South Scotland — a region with abundant access to low-carbon electricity thanks to its strong renewable generation mix.

But this raises an important question:

What happens if you try to produce hydrogen somewhere else?

The Role of the UK Low Carbon Hydrogen Standard (LCHS)

To be certified under the UK LCHS, hydrogen producers must ensure their production stays below 20 gCO₂ per MJ of hydrogen. This isn’t about hitting a yearly average — it’s about running your plant during hours when the electricity you’re using is clean enough to comply or ‘temporal correlation’.

That means your maximum possible hydrogen production rate is fundamentally limited by how often the local grid is below the required carbon intensity threshold.

Regional Grid Carbon Intensity: The Facts

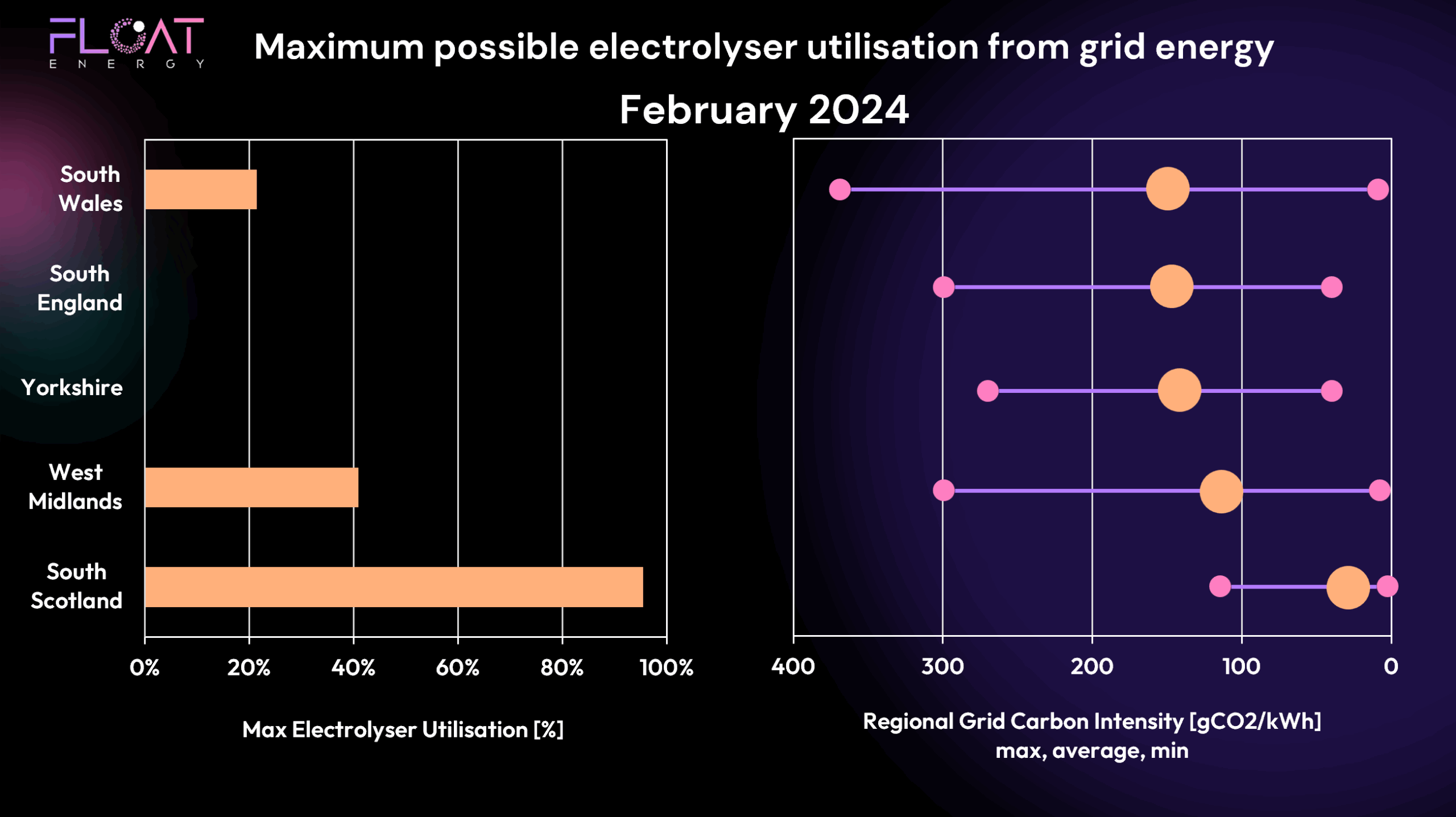

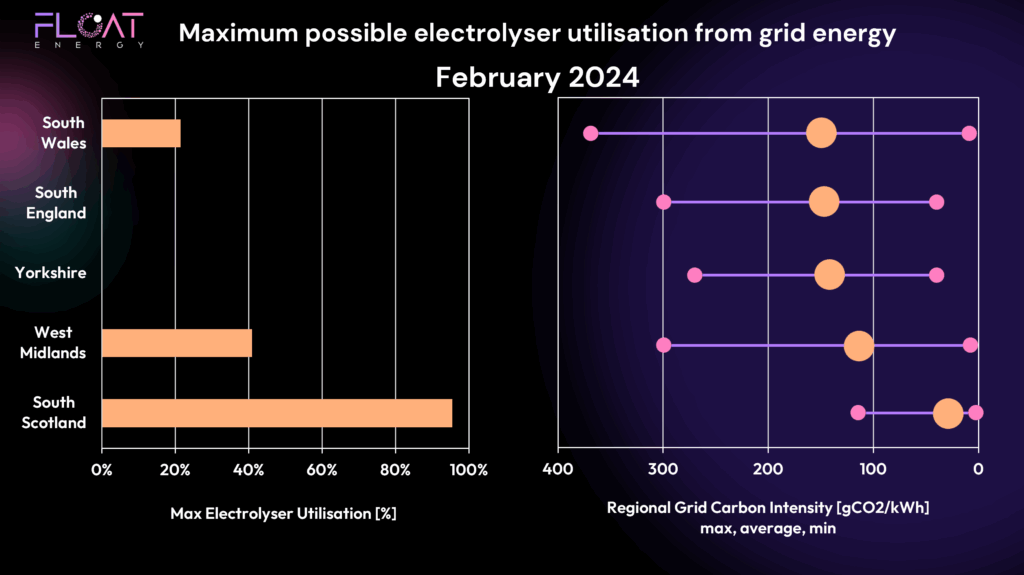

The charts below show two things:

🔹 How often an electrolyser could run within LCHS limits (maximum utilisation %)

🔹 The carbon intensity profile of the grid in each region (min, max, average)

Key Insights:

1️⃣ Scotland is the Clear Standout

- In both winter and summer, South Scotland allows 90-95% utilisation using only grid power while staying compliant with LCHS.

- This reflects its high renewable penetration, particularly wind.

2️⃣ Other Regions Face Major Constraints

- Regions like South Wales, South England, Yorkshire, and West Midlands allow significantly less utilisation.

- In February, some regions could only achieve 10-30% utilisation.

3️⃣ It’s Not About Averages — It’s About Timing

- A lower average carbon intensity doesn’t guarantee high utilisation.

- What matters is how many hours the grid is below the LCHS threshold, not how low the average number looks on paper.

Why Not Just Produce Hydrogen in Scotland?

If Scotland’s grid allows such high utilisation, why don’t all hydrogen projects go there? The answer is practical, not technical:

- Hydrogen is expensive to move.

- There’s currently no established pipeline infrastructure connecting Scotland to the Midlands or South East.

- Moving hydrogen by truck or shipping is costly and inefficient.

As a result, many producers have to site their projects near demand, even if the local grid isn’t as clean.

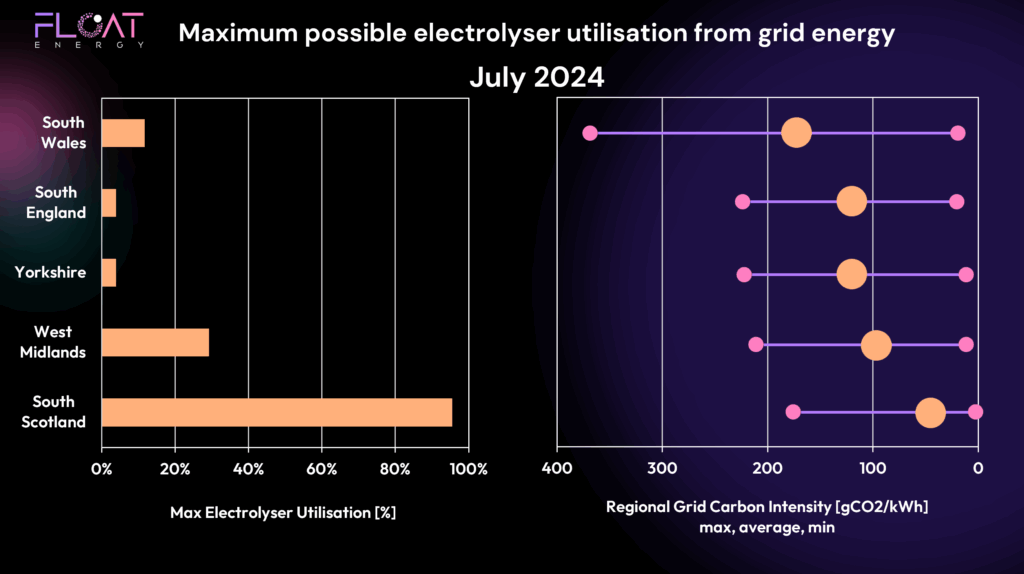

Seasonal Variation: Summer Isn’t a Silver Bullet

While you might expect summer months to offer significantly higher utilisation (thanks to more solar), the reality is more nuanced:

- Some improvement is possible, but not transformative.

- Regions with low utilisation in February don’t suddenly become high-utilisation regions in July.

- Summer months have a big impact on the max carbon intensity, but the hydrogen utilisation is more dependent on the time spent below at low carbon intensity.

This shows the fundamental constraint: without clean, consistent local grid supply, hydrogen production will be limited by carbon thresholds no matter the season.

Can You Increase Utilisation with PPAs?

For hydrogen producers outside of regions like South Scotland, where the grid alone doesn’t allow high utilisation within the LCHS, Power Purchase Agreements (PPAs) offer a way to unlock greater flexibility.

How PPAs Help:

- Guarantee Low-Carbon Supply: A well-structured PPA with a renewable generator (e.g., wind or solar) gives you access to clean electricity, regardless of the grid’s overall carbon intensity.

- Increase Electrolyser Utilisation: Even in regions where the grid is often too carbon-intensive, a PPA allows production during hours when the dedicated generation is available — lifting your utilisation beyond what grid-only operation would permit.

- Support Certification: A PPA linked to renewable assets can provide clear audit trails for carbon compliance, supporting LCHS certification.

But PPAs Aren’t a Silver Bullet:

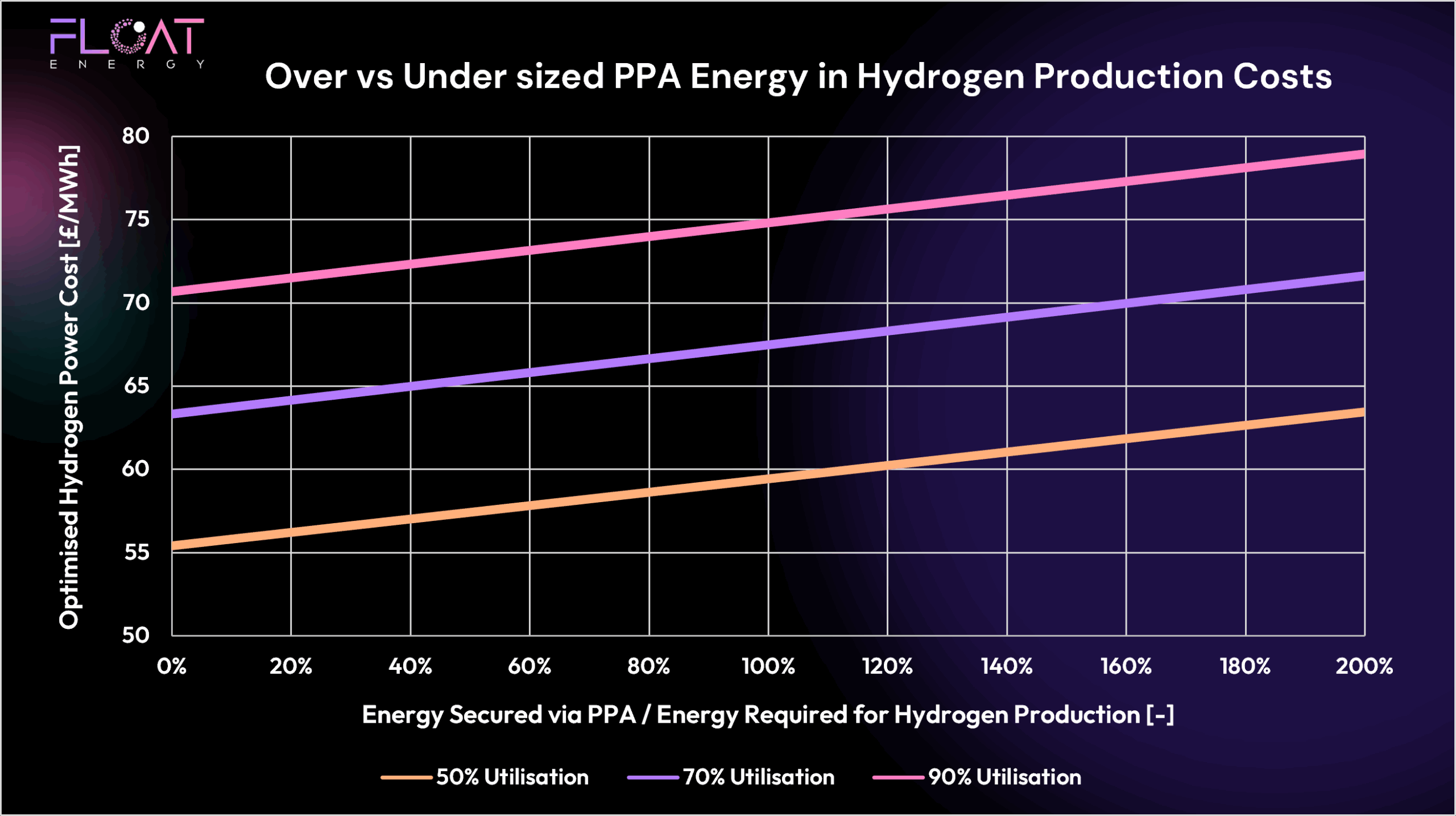

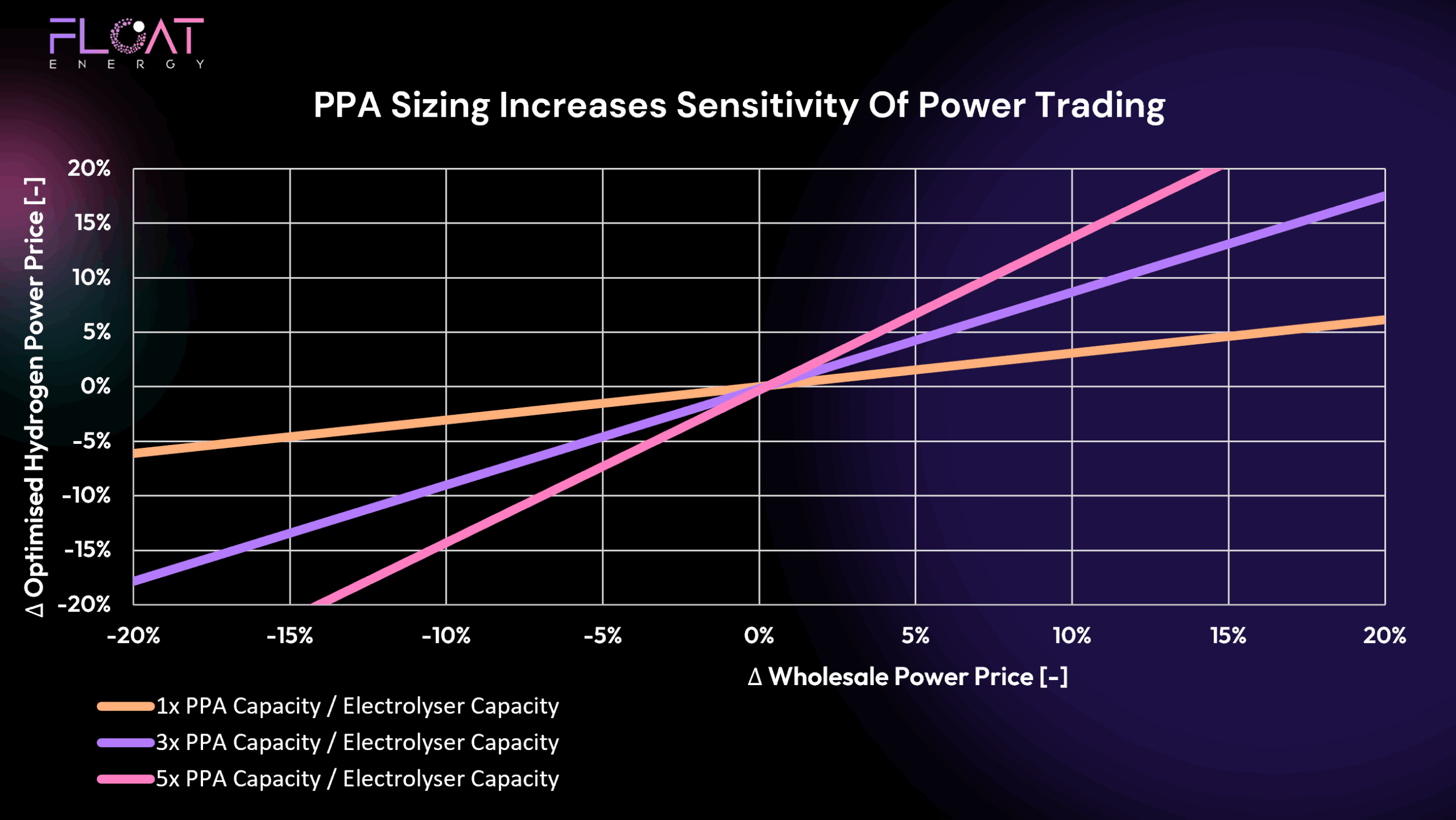

Introducing a PPA also introduces new questions and trade-offs:

- What’s the cost of the PPA compared to grid prices?

- When will the PPA deliver energy? Does it align with your hydrogen production needs, or does it coincide with peak market demand where selling the electricity might offer higher returns?

- How much of the PPA volume will you actually use? Over-contracting renewable supply can lead to wasted energy or missed revenue opportunities.

Why a Clean Grid Makes Hydrogen Procurement Simple for Customers

When it comes to hydrogen production, a clean grid doesn’t just benefit the environment — it simplifies life for customers.

In regions with low-carbon electricity, producing clean hydrogen is straightforward. Customers can plug their electrolyser directly into the grid, purchase electricity through a standard commercial tariff, and know that their hydrogen is compliant with carbon standards like the UK LCHS. There’s no need for complex power contracts or long-term commitments. They can run their electrolyser as much or as little as they want, paying only for what they use. It fits easily within existing procurement models — no change, no hassle. It’s similar to how they are used to paying for gas, diesel or electricity.

But outside of those regions, things get more complicated. Without access to a clean grid, customers need to secure a Power Purchase Agreement (PPA) with a dedicated renewable generator. This introduces a range of new challenges:

- Complexity and Time: Negotiating PPAs isn’t quick or easy.

- Operational Risk: Will the PPA generate when hydrogen is needed? Will it generate enough?

- Commercial Risk: What happens to excess generation? How is the surplus traded or managed?

Long-Term Commitment: PPAs typically lock customers into multi-year deals far longer than a flexible supply tariff.

For many customers, even if hydrogen prices look competitive against existing fuels, adopting hydrogen outside of clean grid regions demands a fundamental change in how they buy, plan, and manage energy. It shifts them from a simple, pay-as-you-go world to a world of risk management, forecasting, and contractual complexity.

That’s why a carbon-clean grid doesn’t just accelerate decarbonisation — it makes hydrogen adoption far more practical for end users. It aligns with how businesses already operate, helping them meet carbon targets without complicating procurement or planning.

Why Optimisation Matters

Whether you’re relying on grid electricity, PPAs, or a combination of both, real-time optimisation remains essential to your hydrogen project’s success.

FLOAT’s optimisation platform helps ensure you:

- Manage carbon compliance by operating within LCHS thresholds.

- Balance grid and PPA usage to capture the best of both worlds.

- Minimise energy costs through intelligent scheduling and dispatch decisions.

We enable hydrogen producers to operate with confidence — reducing exposure to market volatility, protecting compliance, and delivering competitive, clean hydrogen production through real-time control.

📩 Get in touch to discuss how FLOAT can help optimise your project for carbon, cost, and flexibility.

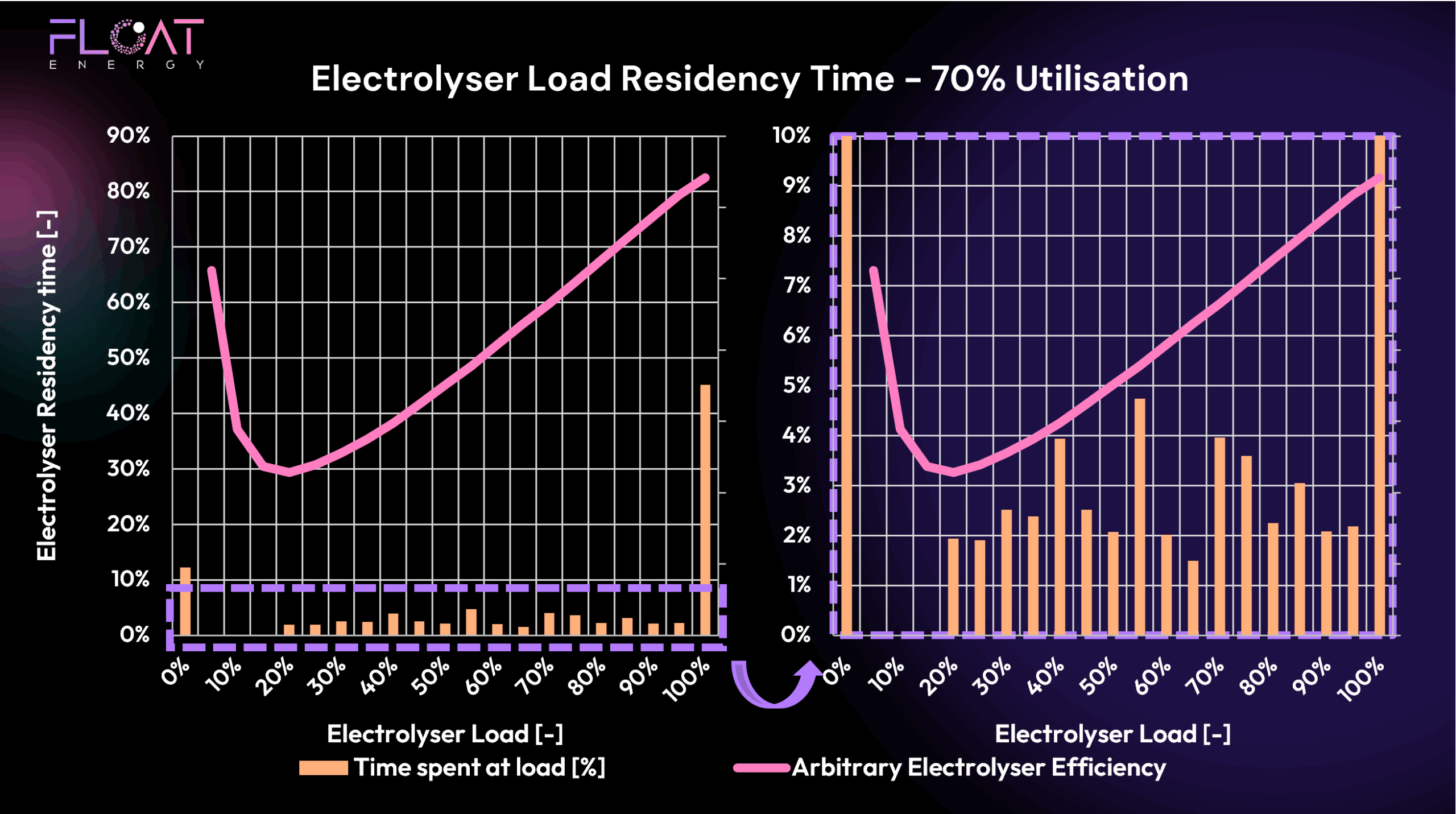

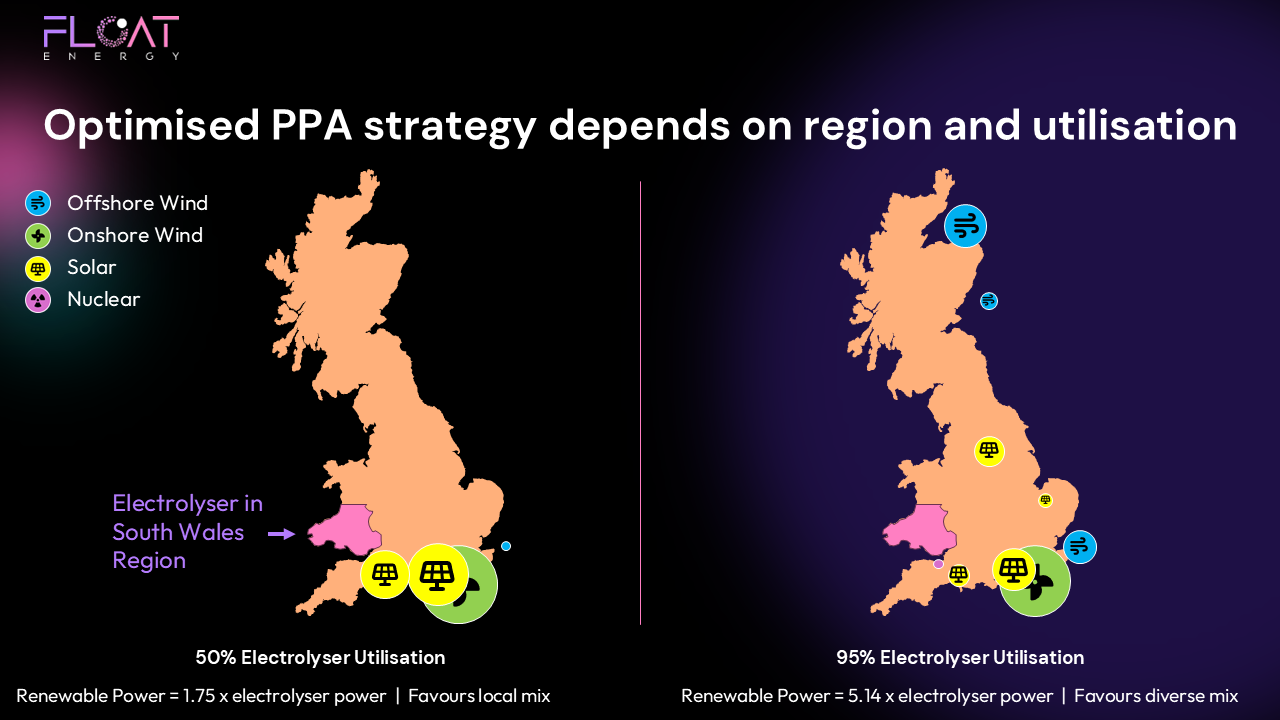

Coming Next: What PPA Do I Need for My Hydrogen Project?

This is a big question and covers a lot of ground. We’ll tackle it in stages starting with sizing for different electrolyser utilisation levels. In future we’ll try to cover everything to help your hydrogen project — including how to balance compliance, cost, flexibility, and bankability.